Why do you need a ball valve?

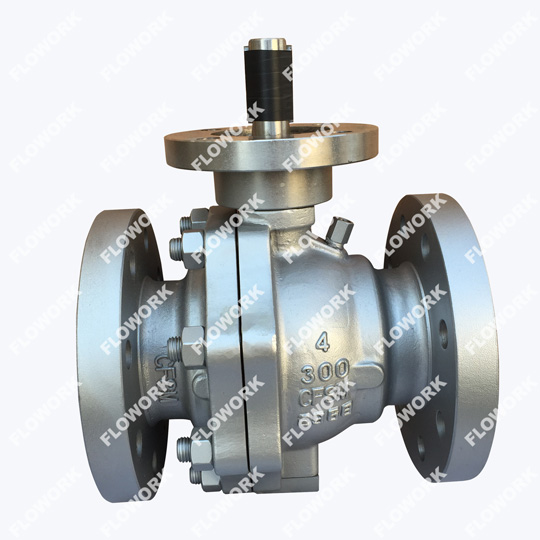

I'm going to talk to you in detail today about why you need a ball valve in various industrial applications. I will delve into the unique advantages of ball valves, including their efficient control capabilities, excellent sealing performance, and versatility in fluid control. By analyzing these characteristics in detail, I will highlight why ball valves are an integral part of many industrial processes. In the field of fluid control, selecting an appropriate valve is critical to ensuring system efficiency and safety. Among many valve types, ball valves stand out for their unique design and superior performance. So, why do you need a ball valve? I will break down the advantages of ball valves and their importance in industrial applications, globe valve manufacture.

1. Efficient control capabilities

The ball valve controls the on and off of the fluid by rotating the ball to achieve fluid control. This design makes the ball valve have the characteristics of rapid opening and closing, and can complete the switching operation in a short time. In addition, the fluid channel of the ball valve is linear and has small fluid resistance, which is beneficial to reducing energy consumption. Therefore, the high-efficiency control capability of ball valves has significant advantages in situations where frequent switching is required or rapid response is required.

2. Excellent sealing performance

The ball valve uses a tight fit between the ball and the valve seat to achieve sealing, and has excellent sealing performance. This sealing structure enables the ball valve to maintain a reliable sealing effect under high pressure, high temperature and harsh environments. In addition, the sealing material of the ball valve can be selected according to the fluid properties and working conditions to ensure sealing performance in various application scenarios, api 6d ball valve.

3. Multifunctionality

Ball valves serve multiple functions in fluid control. In addition to basic on-off control, ball valves can also be used to adjust flow, change fluid direction, and implement emergency shutdown. This versatility enables ball valves to adapt to a variety of complex industrial processes and demand changes, improving system flexibility and adaptability.

4. Durability and maintenance convenience of ball valves

In addition to efficient control capabilities, excellent sealing performance and versatility, ball valves also offer excellent durability and ease of maintenance. This makes it ideal for long-term stable operation and reduced maintenance costs.

Material selection: The main components of ball valves, such as the ball, valve body and valve seat, are usually made of high-strength materials, such as stainless steel, alloy steel, etc. These materials have excellent mechanical properties and corrosion resistance, and can operate stably for a long time in harsh environments, plug valve supplier.

Wear resistance: The sealing surface and ball surface of the ball valve have been specially treated and have excellent wear resistance. Long-term sealing performance and service life are maintained even with frequent switching and high flow rates.

Maintenance convenience: The structural design of the ball valve makes its maintenance relatively simple. For example, many ball valves feature a removable design that allows for easy replacement of seals and actuators. In addition, ball valves are relatively easy to clean, helping to keep them in good working order.

5. Safety and reliability of ball valves

In industrial applications, the safety and reliability of valves are crucial. Ball valves also excel in this regard.

Fire safety: Many ball valves adopt a fire-proof design and can maintain normal operation for a period of time when a fire occurs, providing valuable time for personnel evacuation and fire rescue.

Explosion-proof performance: For certain occasions that require explosion-proof performance, the explosion-proof performance of ball valves is crucial. By using special materials and structural design, ball valves can remain stable under high pressure and high temperature to prevent explosion accidents.

Leak detection and safety alarm: In order to ensure the safety of the system, many ball valves are equipped with leak detection and safety alarm functions. Once leakage or other abnormal conditions are detected, the ball valve will automatically close and trigger the alarm system to notify the operator to take appropriate measures, butterfly valve wholesale.

6. Let me tell you my summary.

Through the in-depth explanation of ball valves’ efficient control, excellent sealing, versatility, wide range of applications, durability and ease of maintenance, and safety and reliability, I can clearly see why one is needed in various industrial applications. ball valve. In the future, with the advancement of technology and changing industrial needs, the design and performance of ball valves will be further improved to meet a wider range of application scenarios and more stringent working environment requirements.