Pressure Balancing Hole of Ball Valves

The pressure balancing hole in a ball valve is a feature designed to equalize pressure on both sides of the ball within the valve. Ball valves are commonly used in various industries to control the flow of fluids. The pressure balancing hole helps to ensure that there is an equal amount of pressure on either side of the ball, which contributes to the smooth operation of the valve.

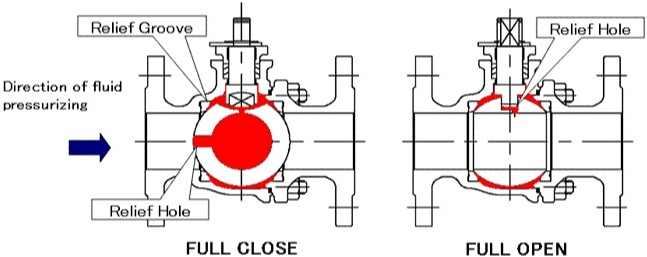

1.Ball valve structure with pressure balancing hole

Ball valves with pressure balancing hole has special design in the internal structure. Generally, it is equipped with a small hole on the ball, which is connected to the pressure in the pipeline and connected to the outlet of the ball valve through the pipeline. It is designed to reduce the pressure differential on both sides of the ball when the ball valve is closed, and to prevent difficulties in closing the ball valve due to excessive medium pressure.

2.Advantages

- Equalize pressure: When the valve is in a closed position, the pressure on both sides of the ball is equalized through the pressure balancing hole. This equalization of pressure helps prevent excessive force on the ball and ensures smoother operation when opening or closing the valve.

- Reduce the impact force generated by the medium passing through the valve and extend the service life of the ball valve.

- Enhance the safety and reliability in operation of ball valve.

- Reduce wear and tear: The pressure balancing feature helps reduce wear and tear on the valve components, improving the overall durability and longevity of the valve.

Ball valves with pressure balancing holes are suitable for applications with high medium pressure, especially when the medium contains solid particles or is corrosive. They are widely used in industries such as chemical, petroleum, and metallurgy. In addition, due to its flexible operation and simple structure, it is also suitable for general fluid control systems.