Views:3

Share:

What is a plug valve?

What is the definition of plug valve?

A valve that opens and closes when the plug body rotates around its axis is called a plug valve.

What is the use of plug valve?

Plug valves are generally used in low and medium pressure, small diameter, and low temperature situations to cut off, distribute and change the flow direction of the medium. Straight-through plug valves are mainly used to cut off the flow of media; three-way plug valves and four-way plug valves are mostly used to change the flow direction of the medium or distribute the medium. When used in high-temperature situations, a lifting plug valve can be used, and the top of the plug is designed with a lifting mechanism. When opening, lift the cock first and disengage it from the sealing surface of the valve body. This valve has small torque, small sealing surface wear and long service life.

The channels of cylindrical cocks are generally rectangular, while the channels of tapered cocks are generally trapezoidal. These shapes allow for lightweight valve construction at the expense of pressure drop. Non-necked circular channels are usually only used in situations where the pipeline needs to be scraped and the properties of the medium do not allow necking. However, some plug valves can only be made into full-circle channels due to the sealing method used.

Plug valves are most suitable for connecting and cutting off media and diverting flow. However, depending on the nature of use and the erosion resistance of the sealing surface, they can sometimes be used for throttling. Since the movement between the sealing surfaces of the plug valve has a wiping effect, and it can completely prevent contact with the flowing medium when fully opened, it can usually also be used in media with suspended particles.

What is a cylindrical plug valve?

The use of plug valves depends to a certain extent on the sealing between the valve plug and the valve body. Cylindrical plug valves often use four sealing methods: using sealant, using valve plug expansion, using O-rings, and using eccentric plugs to wedge into the valve seat.

The cylindrical plug valve is an oil-sealed plug valve. The valve seat sealing of this valve is achieved by the sealant between the valve plug and the valve body. The sealant is injected into the sealing surface through the grease valve and the valve plug rod body with an injection gun. Therefore, when the valve is in use, it can effectively make up for its sealing deficiency by injecting supplementary sealant.

Since the sealing surface is protected from contact with the flowing medium in the fully open position, and the damaged sealing surface is easier to recover, the lubricated plug valve is particularly suitable for abrasive media. However, oil-sealed plug valves are not suitable for throttling, although they are sometimes used for this purpose. This is because the sealant will be washed away from the exposed sealing surface when throttling, so that the seal of the valve seat must be restored every time the valve is closed.

What is a tapered plug valve?

The leakage gap between its seals can be adjusted by firmly pressing the valve plug deeper into the valve seat. When the valve plug is in close contact with the valve body, the valve plug can still rotate, or it can be lifted from the valve body and rotated 90° before sealing.

Tapered plug valves use non-lubricated metal seals. Due to the high friction between this sealing surface, the allowable sealing load must be limited to ensure that the cock can move freely. Therefore, the leakage gap of the sealing surface is relatively wide, so this kind of valve can only achieve satisfactory sealing when using liquids with high surface tension and viscosity. However, this type of valve can also be used with moist gases, such as wet and oily compressed air, if the tap is coated with grease before installation.

The parameter range of the plug valve is as follows: nominal size DN15~500; nominal pressure PN6~100; operating temperature t≤425℃.

What are the types of plug valves?

According to the structural form, plug valves can be divided into the following types: tight-fitting plug valves, packing plug valves, self-sealing plug valves, oil-sealed plug valves, pressure-balanced plug valves, and lift-type plug valves.

What are the characteristics of a plug valve?

① Simple structure, small size and light weight.

② The fluid resistance is small. When the medium flows through the plug valve, the fluid channel does not need to be narrowed, so the fluid resistance is small.

③ Opening and closing is quick and convenient, and the flow direction of the medium is not restricted.

④ The opening and closing torque is large and the opening and closing is laborious. Because the valve body and the plug are sealed by the cone surface, their contact area is large. However, if an oil seal structure is adopted, the opening and closing torque can be reduced.

⑤ The sealing surface is a cone surface, which is large and easy to wear; it is easy to deform and get stuck under high temperatures; the cone surface is difficult to process (grind), it is difficult to ensure sealing, and it is difficult to maintain. However, if an oil seal structure is adopted, the sealing performance can be improved.

What is the main structure of the plug valve?

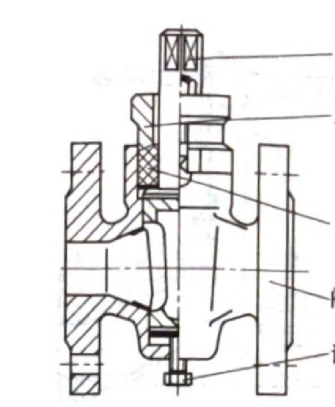

The plug valve is mainly composed of a valve body, a plug body and a packing gland (Figure 1-1).

Figure 1-1 X43 type packing plug valve

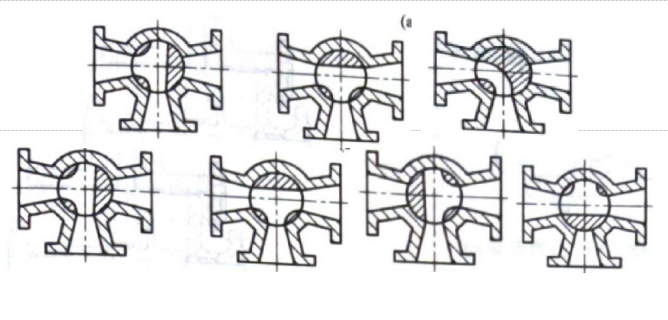

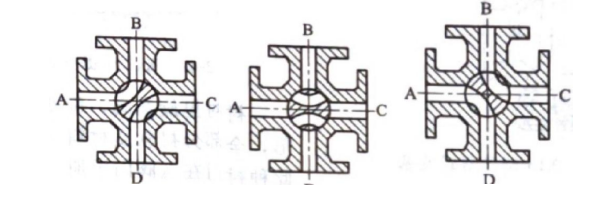

The structure of the valve body includes straight-through type (Figure 1-1), three-way type (Figure 1-2) and four-way type (Figure 1-3).

Figure 1-2 X44 three-way plug valve

Figure 1-3 X45 four-way plug valve

The plug body is the opening and closing part of the plug valve. The plug body and the valve stem are integrated. The top of the cock body is processed into a square head, which can be opened and closed with a wrench. The sealing surfaces of the plug body and the valve body are directly processed from the body. The taper is generally 1:6 or 1:7, and the sealing surface requires high precision. The cock body can use oil seal or metal seal. In low-pressure situations, non-metallic sealing bushing structures can also be used, that is, the valve body is lined with a polytetrafluoroethylene sleeve. The plug channel of the three-way plug valve is L-shaped or T-shaped. The L channel has three distribution forms, and the T-shaped channel has four distribution forms (Figure 1-2). The plug of the four-way plug valve has two L-shaped channels and can have three distribution forms (Figure 1-3).