What is a ball valve and its uses?

What is a ball valve?

A valve in which the ball is driven by the valve stem and rotates around the axis of the valve stem is called a ball valve.

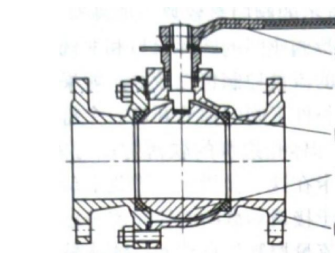

The ball valve is also a plug valve with a spherical closing piece. The valve seat matching the ball is circular, so the sealing stress on the circumference is the same. Most ball valves also use soft seats that conform well to the surface of the ball. Such as PTFE, nylon, etc. Therefore, from the perspective of sealing, the concept of ball valve is excellent. The valve shown in Figure 1-1 is a typical ball valve. The flow control characteristics generated by the circular port moving between the circular valve seats and the double pressure drop between the two valve seats are better. If the valve is partially open for an extended period of time with a high pressure drop across the ball, the soft seal around the edge of the ball hole may slip and possibly trap the ball in this position. Therefore, manually controlled ball valves are most suitable for connecting and cutting off fluid media and performing moderate throttling. If the flow control is automatic and the ball is in continuous motion, the above disadvantages can usually be avoided.

Figure 1-1 Q41F ball valve

Since the movement of the ball between the valve seats has a wiping effect, the ball valve can be used in media with suspended particles. However, abrasive solid particles can damage the valve seat and ball surface, and problems can arise when using ordinary ball valves for media with longer and tougher fiber materials, because these fibers may wrap around the ball.

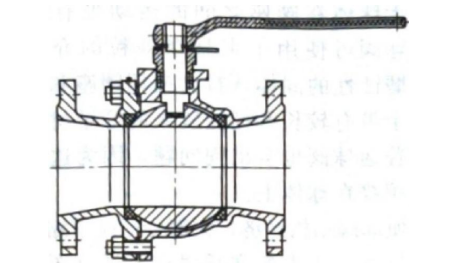

In order to make the ball valve structure economical, most ball valves have a reduced mouth and a Venturi flow channel that is approximately 3/4 of the nominal size (Figure 1-2). The pressure loss of a reduced-bore ball valve is so small that there is usually no reason to add expense to a full-bore ball valve. However, there are some occasions where a non-reducing ball valve must be used. For example, when a pipeline must be cleaned, a full-bore ball valve must be used.

Figure 1-2 Q41F Venturi ball valve

What is the use of ball valve?

The straight-through ball valve is used to cut off the medium and is the most widely used. Multi-way ball valves can change the flow direction or distribute the medium. Ball valves have been widely used in long-distance pipelines. The direction of media flow in ball valves is not restricted. Ball valves have a wide range of pressure and diameter, but the operating temperature is limited and restricted by the sealing ring material.

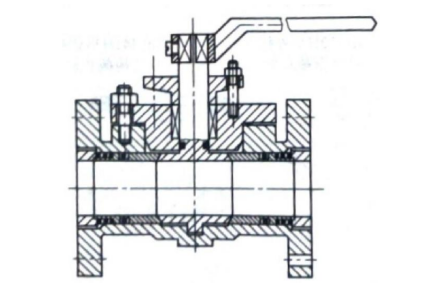

Due to the emergence of hard-sealed ball valves (Figure 1-3), the applicable pressure and applicable temperature of ball valves have been greatly improved. The applicable temperature has increased from -50 to 200°C to -200 to 450°C, and even 600 to 700°C. The pressure has increased from PN40 to PN320, especially the emergence of various lined ball valves, which has further expanded the applicable media of ball valves.

Figure 1-3 Q41H type hard seal fixed ball valve

Ball valve is the valve type that has developed the most significantly in recent decades. In particular, large-diameter ball valves have gone beyond the traditional use concepts of flow relief and flow interruption, and more and more stop valves are being developed to replace traditional throttling. With the development of ball valve structure, the development of materials used, especially the improvement of internal parts structure, its scope of use has also expanded.

What are the advantages of ball valves? In the throttling process industry, it has broken the dominance of globe valves and has become the fastest growing type of valve in the industrial field of control valves. This is because the ball valve that rotates 90° to open and close plays an important role in flow control. It has greater advantages than stop valves:

① Unlike the stop valve, when the valve stem passes through the packing when opening and closing, it is easy to strain the packing and leak out the medium, which can easily cause the valve stem to corrode in the atmosphere;

② Due to the development of driving device and positioner technology, especially the application of computer integrated processing system (CTPEM), 90° rotating opening and closing valves including ball valves are more suitable for use in control systems;

③ The adjustment range is large. The flow adjustment range of a ball valve of the same size is 10 to 20 times larger than that of a globe valve. The flow control range of a ball valve (that is, the ratio of the maximum control flow to the minimum control flow) is more than 100:1;

④It has a wide range of specifications and many series, and can be used to control various media including mud and granular media;

⑤It is a secondary control.

It is reported that standard ball valves can achieve moderate throttling control with appropriate modifications (such as the connection between the ball and the valve stem). However, in order to overcome problems such as noise and cavitation that may occur during throttling control, many manufacturers have introduced ball valves with improved internal parts to replace stop valves for demanding throttling control.

What is a sector ball valve?

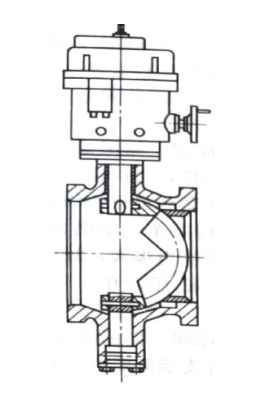

Another representative control valve is the sector ball valve, or V-shaped ball valve, as shown in Figure 1-4. It uses part of the ball's circumference to control the fluid. The valve body is usually integral, and the valve stem and ball can be integrated, or they can be splined and fixed with fixed pins to ensure the stability of opening and closing. It adopts metal seal, and the edge of the sealing seat is sharp, which has a cutting effect on fibrous materials. In addition, the sealing seat is always in contact with the spherical fan surface, which can prevent granular media from adhering to the fan surface. Therefore, this kind of valve is also widely suitable for mud and belt applications. The granular media is especially suitable for pulp media in paper mills and can cut the fibers in the pulp. Because it is a straight-through flow channel, its throttling amplitude changes in a wide range, about 300:1, which allows precise control over a larger flow range and is suitable for control of metering and batching.

Figure 1-4 Q970V-shaped regulating ball valve