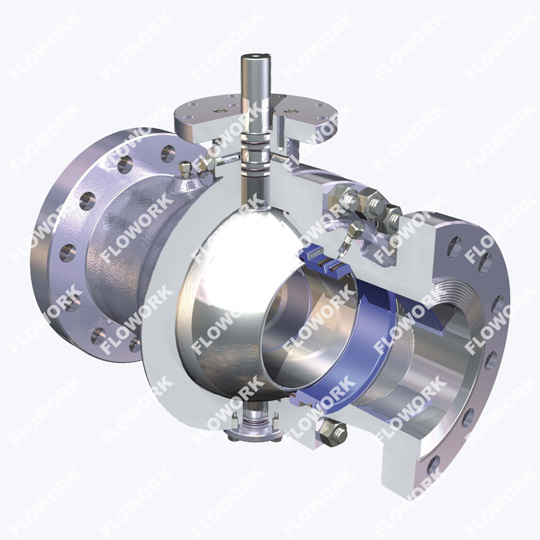

What are examples of fugitive emissions ball valve?

Practical application examples of fugitive discharge ball valves. When I discuss the subject of fugitive emissions ball valves, I am actually discussing a specific type of valve that is primarily used to control and reduce fugitive emissions of pollutants from industrial processes. Fugitive emissions refer to harmful gases and pollutants that are inevitably emitted through chimneys, pipes, openings, etc. during the production process. The fugitive discharge ball valve is designed to control these emissions more effectively. Next, let me talk about the practical application case of unorganized discharge ball valve, cast steel check valve.

1. Application cases

Fugitive discharge ball valves play an important role in various industrial applications. Here are some actual fugitive discharge ball valve application cases:

Steel manufacturing: During the steel manufacturing process, blast furnaces and converters generate large amounts of waste gas. These exhaust gases contain a large amount of harmful substances, such as sulfides, nitrogen compounds and smoke. The unorganized emission ball valve can accurately control the emission of these waste gases and ensure that the escape of harmful substances is effectively controlled.

Petrochemical industry: A large amount of organic waste gas and acidic waste gas will be generated during the petrochemical production process. If these waste gases are directly discharged into the atmosphere, they will have a serious impact on the environment. The unorganized emission ball valve can effectively collect and process these waste gases and reduce environmental pollution.

Thermal power generation: Thermal power stations will produce a large amount of smoke, which contains a large amount of harmful substances, such as sulfides, nitrogen compounds and soot. The unorganized emission ball valve can effectively treat these flue gases and reduce environmental pollution.

Pharmaceutical manufacturing: Various harmful gases are produced during the pharmaceutical manufacturing process, such as chloroform, toluene, etc. If these gases are directly discharged into the atmosphere without treatment, they will have a serious impact on the environment. The unorganized discharge ball valve can effectively collect and process these gases and reduce environmental pollution, high temperature check valve.

These examples are just a few of the fugitive discharge ball valve applications. With the continuous improvement of environmental protection requirements and the continuous development of technology, the technology of unorganized discharge ball valves is also constantly improved and perfected. In the future, unorganized discharge ball valves will be more intelligent, efficient and reliable, making greater contributions to environmental protection.

2. Challenges of unorganized discharge ball valves

As an effective environmental protection device, fugitive emission ball valves play a key role in controlling emissions from industrial processes. However, in practical applications, fugitive discharge ball valves still face some challenges and problems.

First of all, the reliability of the fugitive discharge ball valve is an important issue. Due to the complexity and continuity of industrial processes, fugitive discharge ball valves need to have a high degree of reliability and stability to ensure long-term stable operation. If a fugitive discharge ball valve malfunctions or fails, serious environmental problems can result. Therefore, improving the reliability and stability of fugitive discharge ball valves is an important challenge currently faced, socket weld check valve.

Secondly, the energy efficiency of fugitive discharge ball valves is also an issue that needs attention. In terms of energy consumption, unorganized discharge ball valves require effective energy conversion and control to ensure full utilization of energy and reduce energy waste. At the same time, improving the energy efficiency of fugitive emission ball valves will also help reduce carbon emissions and environmental pollution.

In addition, the intelligence and automation of unorganized discharge ball valves are also future development trends. With the continuous development of industrial automation, unorganized discharge ball valves also need to have intelligent control and monitoring functions to achieve automated operation and remote management. By introducing intelligent and automated technologies, the operating efficiency and management level of unorganized discharge ball valves can be greatly improved.

Finally, material selection and environmental performance of fugitive discharge ball valves are also factors to consider. The material of the unorganized discharge ball valve needs to be resistant to corrosion, high temperature, and wear to ensure long-term stable operation. At the same time, unorganized discharge ball valves also need to comply with environmental protection requirements and use environmentally friendly materials and processes to reduce negative impacts on the environment, api 6d check valve.

3. Future development of unorganized discharge ball valves

In the future, with the continuous improvement of environmental protection requirements and the continuous development of technology, unorganized discharge ball valves will continue to be improved and perfected. By improving reliability, energy efficiency, intelligence and automation levels, and environmental performance, fugitive emission ball valves will play a more important role in environmental protection and contribute to creating a cleaner and more sustainable future.