Can A Swing Check Valve Be Installed Vertically?

Can swing check valves be installed vertically?

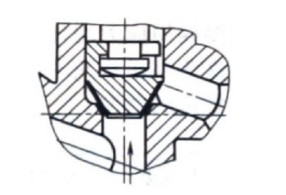

Whether the swing check valve can be installed vertically is actually related to the type and design of the valve. Let’s talk about this topic in detail. Swing check valve is a common valve type, mainly used to prevent the backflow of media. It opens or closes by rotating the valve disc in the valve seat, thereby achieving one-way flow of the medium. This type of valve is commonly used in equipment such as pipelines, pumps, and storage tanks.

So can the swing check valve be installed vertically? Most check valves can be installed vertically, but whether they can be installed vertically depends on the design and specifications of the valve.

1. We need to understand the design principles of valves. The disc of the swing check valve is usually closed by spring or gravity. When the medium flows, the fluid pressure acts on the valve disc, overcoming the force of the spring or gravity, causing the valve disc to rotate and open. When the medium stops flowing, the spring or gravity resets the valve disc and closes the valve.

2. For most common swing check valves, the valve can be installed vertically. When installed vertically, the inlet and outlet directions of the valve are the same as when installed horizontally, except that the entire valve is vertical to the ground. At this time, the valve seat and disc of the valve can still work normally and will not be affected by changes in the installation angle.

3. It should be noted that when installing vertically, the position and height of the valve must be appropriate to facilitate the flow of media and operation and maintenance. Pipe support and fixation issues also need to be considered to ensure that the valve is stable and reliable during use.

4. Swing check valves can be installed vertically in most cases, but whether they can be installed vertically needs to be determined based on the design and specifications of the valve.

What are the specifications of swing check valve?

1. The specifications of swing check valve are usually described by two main parameters: nominal diameter and valve body material. The nominal diameter is the inlet and outlet diameter of the swing check valve and is an important basis for selecting the valve. Common nominal diameters range from DN15 to DN800, depending on the valve's application scenario and design requirements.

2. The valve body material is also a factor that needs to be considered when selecting a valve. Common valve body materials include cast iron, carbon steel, alloy steel, stainless steel and brass. Valves made of different materials have different corrosion resistance and wear resistance, and are suitable for different fluid media and working conditions. Swing check valves also have other specifications, such as connection methods (such as flange connection, threaded connection, welded connection), working pressure and working temperature, etc. These parameters also influence valve selection and use.

What is the function of swing check valve?

Swing check valve, also known as rotary check valve, is a common valve type. Its main function is to prevent the medium from flowing back and ensure that the fluid can only flow in one direction. Medium backflow refers to the phenomenon of fluid flowing in the opposite direction in a pipeline. In many industrial equipment and systems, fluids require one-way flow to ensure normal operation of the equipment. If media backflow occurs, it may cause equipment damage, pipe rupture, media waste and contamination, etc.

1. The function of the swing check valve is to prevent the medium from flowing back. It opens or closes by rotating the valve disc in the valve seat, thereby achieving one-way flow of the medium. When fluid pressure acts on the valve disc, the valve disc rotates open against the force of the spring or gravity, allowing the medium to flow normally. When the medium stops flowing or the pressure disappears, the spring or gravity resets the valve disc and closes the valve, thereby preventing the medium from flowing back.

2. In addition to preventing the backflow of media, the swing check valve also has other functions. For example, it can be used as a regulating valve to control the flow and pressure of the medium by changing the opening angle of the valve disc. Some specially designed swing check valves are also shock-proof, noise-proof, wear-resistant, corrosion-resistant and can adapt to various complex working environments and fluid media.

The function of swing check valve is very extensive and important. It can effectively prevent the backflow of media, protect equipment and pipelines from damage, and maintain the one-way flow of media and stable working conditions. At the same time, swing check valves also have various functions such as regulating flow and pressure, preventing shocks, and preventing noise. They are an indispensable part of industrial equipment and systems.