The Benefits of Using Plug Valves in Low-Flow and High-Pressure Systems

Introduction

When selecting valves for fluid control systems, it's crucial to understand the different types of valves and their applications. Plug valves, known for their simple design and reliability, offer distinct advantages in both low-flow and high-pressure systems. This article explores the benefits of plug valves and how they excel in controlling fluid flow under varying conditions.

What Are Plug Valves?

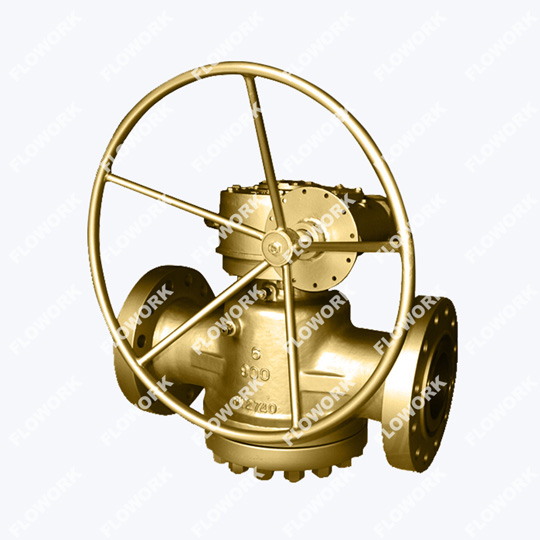

Plug valves are quarter-turn valves that control fluid flow by rotating a plug inside the valve body. The plug has one or more holes, which align with the inlet and outlet ports when the valve is in the open position. Plug valves are typically used for on/off and throttling control in various industrial applications. Their design makes them ideal for handling high-pressure fluids and low-flow conditions, providing efficient flow control with minimal leakage.

How Plug Valves Benefit Low-Flow Systems

Plug Valve Efficiency in Low Flow

Plug valves are highly effective in low-flow systems due to their ability to regulate flow rates accurately. Their simple design and ability to seal tightly prevent any leakage, even in systems requiring precise control. This makes them ideal for industries such as water treatment and chemical processing, where consistent and reliable flow control is essential, even at lower flow rates.

Advantages of Plug Valves in Tight Flow Control

In low-flow systems, precision is key, and plug valves are built for this task. They offer a higher degree of control over the flow rate compared to other valve types, such as ball valves, making them ideal for systems with strict flow control requirements. Their tight shut-off capability ensures that the flow can be completely stopped or precisely adjusted without any loss, making them a trusted choice for critical operations.

How Plug Valves Handle High-Pressure Systems

Pressure Management with Plug Valves

One of the standout features of plug valves is their ability to handle high-pressure systems. Their robust construction allows them to withstand the stresses of high-pressure environments, maintaining performance even under extreme conditions. This makes them suitable for applications in industries such as oil and gas, power generation, and chemical manufacturing, where managing pressure is critical.

Why Plug Valves Excel in High-Pressure Systems

Plug valves excel in high-pressure systems due to their strong sealing capability and minimal internal friction. The plug's tight seal ensures that no leakage occurs, even in systems where pressure fluctuations are common. Their ability to handle both pressure and flow control efficiently makes them a preferred choice for many high-pressure applications.

Design and Selection Considerations for Plug Valves

Flow Rate and Pressure Requirements

When selecting a plug valve, it's important to consider both the flow rate and pressure requirements of your system. Plug valves are particularly effective for systems requiring high-pressure handling and precise flow control. If your system involves fluctuating pressures or low to medium flow, plug valves can offer the flexibility needed to maintain stability and efficiency.

Material and Design Considerations for Plug Valves

The material selection for plug valves is crucial for ensuring durability and performance. Common materials for plug valves include stainless steel, brass, and various alloys, depending on the fluid's corrosiveness and the temperature range. Proper material selection ensures the valve can withstand the conditions of your system, whether it's high-pressure steam or aggressive chemicals.

Cost and Maintenance Factors

Plug valves are generally cost-effective and easy to maintain due to their simple design. The maintenance process involves regular inspections for wear, as the plug's sealing surfaces are subject to friction. However, their reliability and ease of operation make them a good investment for many systems, particularly where ongoing maintenance costs need to be minimized.

Applications of Plug Valves in Various Industries

Industrial Applications for Plug Valves

Plug valves are widely used in various industries, including oil and gas, water treatment, food processing, and chemical manufacturing. Their ability to handle high pressures and control low-flow rates makes them indispensable in these industries, where precise flow control is critical to operations.

Plug Valves in Fluid Handling Systems

In fluid handling systems, plug valves are employed to regulate the flow of liquids, gases, or slurries. Their ease of operation and reliability ensure that the system functions optimally, even under harsh conditions. They are commonly used in pipeline systems, pumping stations, and fluid storage tanks.

FAQs

What is a plug valve and how does it work?

A plug valve is a quarter-turn valve used to control fluid flow. It works by rotating a plug inside the valve body, aligning holes in the plug with the valve ports to allow or block the flow of fluid.

What are the advantages of using plug valves in low-flow systems?

Plug valves provide excellent flow control in low-flow systems due to their precise regulation and tight sealing, ensuring minimal leakage and consistent performance even at low flow rates.

Are plug valves suitable for high-pressure applications?

Yes, plug valves are ideal for high-pressure applications because of their robust construction and strong sealing capabilities, making them capable of handling extreme pressures without leakage.

Conclusion

Plug valves offer significant benefits in both low-flow and high-pressure systems. Their ability to provide precise flow control, handle high pressures, and offer long-lasting performance makes them a reliable choice for many industrial applications. If you are looking for high-quality plug valves for your fluid control needs, visit Flowork, where we offer a range of plug valves designed to meet the demands of various industries.