1、You are in restricted area and need password. Please Contact us to obtain documents.

2、PasswordIf you have any questions about quotation or cooperation, please feel free to send us inquiry. Inquiry us

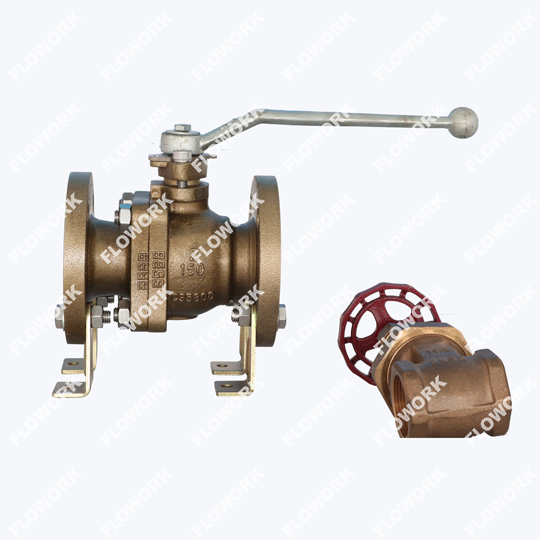

| Size: | 2"-24" |

| Pressure: | 150LB-2500LB |

| Body Material: | C95800, C95500, C95200, C95300, C95600, C61900, C63200, etc. |

| Seal Material: | PEEK, RPTFE, PTFE, DEVLON, HNBR, NYLON, AFLAS,etc. |

| Connection Type: | Flanged, Butt Welded, Socket Welded, NPT |

| Operation: | Hand lever, gear operated, pneumatic, motorized |

| Face to Face Dimension: | ASME B16.10 |

| Flange End Dimension: | ASME B16.5 |

| Butt Welded Dimension: | ASME B16.25 |

| Design and Manufacture: | API 6D |

| Test Standard: | API 598, API 607, API 6FA, ISO 15848-1-2 |

Available with material Nickle aluminum bronze, Aluminum bronze, Tin bronze, etc.

Available with soft seal and hard seal.

Fire-safe and anti-static design, blow-out proof stem.

connection type: NPT, flanged, SW, etc.

High intensity, abrasion resistance and corrosion resistance.

Suitable for harsh working conditions that need to withstand highly corrosive environment, especially for subsea applications.

The applicable temperature range for bronze ball valves can vary depending on the specific alloy of bronze used and the type of sealing materials inside the valve. Bronze itself has a relatively wide temperature tolerance, but other components, such as gaskets or seats, may have temperature limitations. Here's a general guideline for the temperature range of bronze ball valves:

Standard Bronze: Standard bronze ball valves, typically made from materials like C83600 or C84400, are suitable for temperatures ranging from -20°F to 400°F (-29°C to 204°C). This range is suitable for many water and general-purpose applications. api 6d ball valve

High-Temperature Bronze: Some bronze alloys are designed to handle higher temperatures. These valves can operate in the range of -20°F to 500°F (-29°C to 260°C) or even higher, depending on the specific alloy composition.

It's important to note that the temperature range can be influenced by factors such as the type of seats and seals used in the valve. For example, valves with PTFE (Teflon) seats and seals may have a lower maximum temperature rating compared to valves with metal seats or other high-temperature sealing materials.

When selecting a bronze ball valve for a specific application, it's crucial to consider both the temperature of the medium being controlled and the ambient temperature. If the temperature falls outside the recommended range for the valve, it may lead to performance issues, leakage, or damage to the valve components.

Additionally, consult the manufacturer's specifications and guidelines for the particular bronze ball valve you plan to use, as they may provide specific temperature ratings and limitations for that valve model. If you're dealing with extreme temperatures or critical applications, it's advisable to seek guidance from a qualified engineer or valve manufacturer to ensure you choose the right valve for your needs. forged ball valve

Bronze ball valves are typically used in a variety of circumstances and applications, thanks to their corrosion resistance, durability, and versatility. Here are some common circumstances and industries where bronze ball valves are often employed:

Plumbing: Bronze ball valves are commonly used in plumbing systems to control the flow of water in residential, commercial, and industrial settings. They are used for applications such as regulating water supply, shut-off valves, and controlling water flow in pipelines.

Marine Applications: Due to their resistance to saltwater corrosion, bronze ball valves are widely used in marine and shipbuilding industries for controlling seawater flow, bilge systems, and other maritime applications. carbon steel gate valves

Hydronic Heating Systems: Bronze ball valves are suitable for use in hydronic heating systems, where they regulate the flow of hot water or glycol-based heating fluids.

Oil and Gas Industry: In non-corrosive oil and gas applications, bronze ball valves can be found, including controlling the flow of hydrocarbons, natural gas, and other related fluids.

Steam Systems: Bronze ball valves can handle high-temperature steam, making them suitable for use in steam pipelines and systems.

Compressed Air Systems: They are used to control the flow of compressed air in various industrial settings.

Chemical Processing: In applications where the chemicals are not highly corrosive or reactive with bronze, these valves can be used for regulating chemical flow.

Fire Protection Systems: Bronze ball valves are used in fire protection systems to control water flow for fire sprinklers and fire hydrants.

Agriculture: They can be found in agricultural irrigation systems to control the flow of water to crops.

Food and Beverage Industry: Bronze ball valves are used in food and beverage processing facilities for controlling the flow of liquids and fluids.

HVAC (Heating, Ventilation, and Air Conditioning): They are employed in HVAC systems for regulating the flow of water or other fluids used in heating and cooling processes.

General Industrial Applications: Bronze ball valves can be used in a wide range of industrial processes where a durable and corrosion-resistant valve is needed.

It's important to note that while bronze ball valves are versatile and can be used in many applications, the specific choice of valve materials and design should always be based on the compatibility with the medium being controlled and the operating conditions. Factors such as temperature, pressure, and the chemical properties of the medium should be carefully considered when selecting a valve to ensure optimal performance and safety. Consulting with a qualified engineer or valve manufacturer is advisable for critical or specialized applications.

The lifespan of bronze ball valves can vary significantly depending on several factors, including the quality of the valve, its intended use, the environment it operates in, and how well it is maintained. In general, bronze ball valves are known for their durability and can provide reliable service for many years. Here are some key factors that can influence the longevity of bronze ball valves:

Quality of Manufacturing: The quality of the valve's construction and the materials used can significantly impact its lifespan. Valves manufactured to higher quality standards and with better materials are likely to last longer. high temperature gate valves

Operating Conditions: The environment in which the valve is used plays a crucial role. Factors such as temperature, pressure, fluid type, and the presence of corrosive or abrasive substances can affect the valve's lifespan. For example, valves used in harsh or corrosive environments may wear out faster.

Maintenance and Care: Regular maintenance and proper care can extend the lifespan of bronze ball valves. This includes routine inspections, lubrication, and addressing any issues promptly.

Frequency of Use: The frequency with which the valve is operated can also influence its lifespan. Valves that are frequently cycled may experience more wear and tear than those in less active systems.

Load and Stress: Excessive stress or overloading of the valve can lead to premature wear or failure. It's essential to operate the valve within its specified limits and avoid subjecting it to undue stress.

Manufacturer's Recommendations: Following the manufacturer's recommendations for installation, operation, and maintenance is crucial for maximizing the lifespan of any valve, duplex stainless steel ball valve.

In many industrial applications, bronze ball valves can last for several years or even decades when properly maintained and used within their design parameters. However, it's essential to consider the specific application and conditions when estimating the valve's expected lifespan. Additionally, regulatory and safety considerations may require periodic valve replacement or inspection, even if the valve appears to be in good working condition.

Bronze ball valves can be designed and manufactured to meet specific standards for low leakage, but their ability to do so depends on factors such as valve design, construction, and quality. Achieving low leakage in a valve typically involves factors like the type of seals used, the precision of machining, and the overall design of the valve.

Low leakage in ball valves is typically quantified by valve classes defined in standards like API 598 (American Petroleum Institute) or ISO 5208 (International Organization for Standardization). These standards categorize valves into different leakage classes, such as Class I, Class II, and Class III, with Class I having the lowest allowable leakage and Class III having the highest, fugitive emission gate valve.

Bronze ball valves can meet lower leakage standards (e.g., Class I) when designed and manufactured to do so. Achieving low leakage typically involves features such as:

High-Quality Seals: The seals used in the valve, such as the seats and stem seals, should be of high quality and made from suitable materials to minimize leakage.

Precision Machining: The valve components should be machined to tight tolerances to ensure proper sealing when the valve is closed.

Suitable Design: The valve design, including the shape of the ball and the seating arrangement, should be optimized for sealing performance.

Testing and Certification: The valves should undergo rigorous testing to verify their performance and leakage rates, and they may need certification to meet specific standards.

It's important to note that not all bronze ball valves are designed for low-leakage applications, and their suitability for a particular use case should be verified by consulting the manufacturer's specifications and testing data. Additionally, bronze ball valves may not be the best choice for extremely critical low-leakage applications, where materials like stainless steel or specialized alloys are often preferred due to their superior sealing capabilities and corrosion resistance.

Send us a message if you have any questions or request a quote.

A reply from our experts within 24 hours

The latest detailed product catalugue

One-stop service for your project