How Bronze Valves Reduce Maintenance Costs in Fluid Systems

Introduction

You want your fluid systems to operate efficiently while minimizing downtime and maintenance costs. Choosing the right valves is crucial. Bronze valves offer exceptional durability and corrosion resistance, making them an ideal solution. By understanding their benefits, you can improve system reliability and save time and money on maintenance tasks across industrial operations.

What Are Bronze Valves?

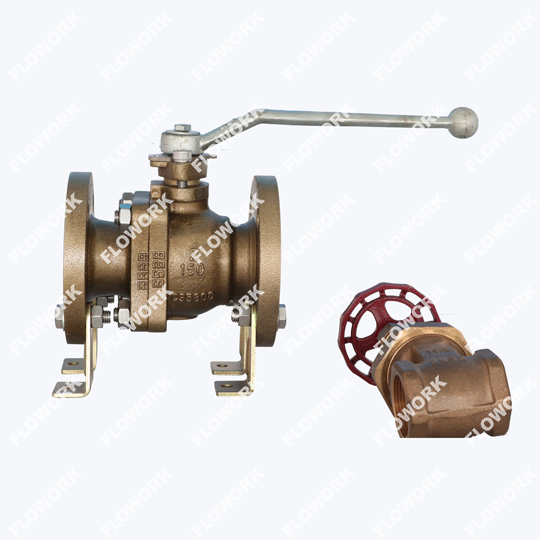

Structure and Composition of Bronze Valves

Bronze valves are made from copper-tin alloys, often with small additions of other metals to enhance strength and corrosion resistance. This composition makes them highly suitable for harsh and corrosive fluid environments.

How Bronze Valves Differ from Other Valves

Unlike valves made from steel or iron, bronze valves resist rust, scaling, and chemical degradation. Their longevity reduces replacement frequency and lowers maintenance demands over time.

How Bronze Valves Reduce Maintenance Costs

Corrosion Resistance for Long-Term Use

Bronze valves withstand corrosive fluids like acids, seawater, and chemical solutions. Their resistance prevents leaks and failures, cutting down on repair costs and system downtime.

Minimizing Wear and Tear

The smooth surfaces of bronze valves reduce friction in moving parts, preserving seals and gaskets. This leads to longer service life and less frequent part replacement.

Simplifying Maintenance Procedures

Bronze valves often require minimal lubrication and are easy to clean. Routine checks are simpler and faster, saving labor costs and avoiding prolonged system shutdowns. Choosing bronze valves ensures your systems remain reliable with minimal intervention.

Applications of Bronze Valves in Fluid Systems

Chemical Processing Systems

In chemical plants, bronze valves handle corrosive liquids safely. They maintain flow control and prevent contamination while lowering maintenance frequency.

Water Treatment and Plumbing

Bronze valves are ideal for municipal and industrial water systems. Their corrosion resistance ensures reliable operation and reduced maintenance over years of service.

Industrial Fluid Handling

In oil, gas, and other industrial sectors, bronze valves sustain high-performance fluid control under challenging conditions, contributing to cost-effective operations.

FAQs

What makes bronze valves ideal for reducing maintenance costs?

Bronze valves resist corrosion and wear, leading to fewer repairs and replacements over time.

Can bronze valves handle aggressive chemical fluids?

Yes, they are designed for acids, salts, and other corrosive liquids in industrial systems.

Do bronze valves require frequent lubrication?

No, their design minimizes friction, reducing the need for constant lubrication.

Conclusion

You can significantly reduce maintenance costs by choosing durable bronze valves for your fluid systems. From chemical processing to water treatment, they provide reliable performance and longevity. For high-quality solutions, explore flowork and enhance your system efficiency with dependable bronze valves.