How Ball Valves Improve Flow Efficiency in Industrial Pipelines

Introduction

You need reliable valves to maintain optimal flow in your industrial pipelines. Ball valves are widely used because they offer minimal resistance, fast operation, and long-term durability. Understanding how they improve flow efficiency helps you choose the right valves for your systems, reduce energy costs, and ensure smooth operations.

Overview of Ball Valves

What Are Ball Valves

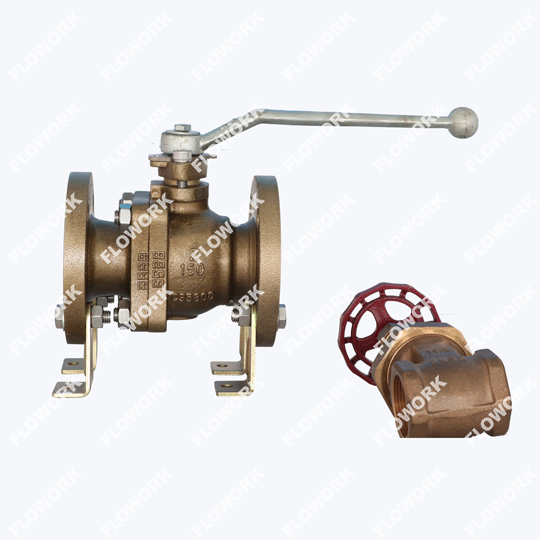

Ball valves are quarter-turn valves with a spherical disc that controls fluid flow. When the ball’s hole aligns with the pipeline, fluid flows freely; when rotated 90 degrees, flow stops completely. Their simple design allows for fast and reliable operation.

Key Advantages in Industrial Pipelines

Ball valves provide excellent sealing, low pressure drop, and high flow capacity. They are suitable for various media, including water, chemicals, and gases, making them versatile for industrial applications.

How Ball Valves Enhance Flow Efficiency

Minimal Flow Resistance

The straight-through flow path of ball valves reduces turbulence and pressure loss. Unlike globe or gate valves, they maintain high flow rates even under high-pressure conditions.

Quick Operation and Control

Ball valves allow rapid opening and closing, reducing the time needed for adjustments. This feature improves process efficiency and ensures accurate control of fluid distribution.

Low Maintenance and Durability

Due to their simple design and fewer moving parts, ball valves require less maintenance and have a longer service life. This reliability contributes to consistent flow efficiency over time.

Industrial Applications of Ball Valves

Ball valves are ideal for pipelines in chemical plants, water treatment facilities, oil & gas systems, and food processing industries. They help maintain steady flow, prevent leakage, and allow operators to control processes efficiently.

FAQs

How do ball valves improve flow efficiency?

By providing a straight-through flow path, ball valves minimize turbulence and pressure loss, maintaining high flow rates.

Can ball valves handle high-pressure systems?

Yes, they are designed for high-pressure and high-temperature applications, ensuring durability and reliability.

What maintenance is required for ball valves?

Minimal maintenance is needed due to their simple design, but regular inspection ensures long-term performance.

Conclusion

You can improve pipeline performance and reduce operational costs by choosing high-quality ball valves. Flowork ball valves offer reliable solutions for industrial systems, enhancing flow efficiency and ensuring safe, long-term operation.